There are a range of modern mining technologies used in today’s mines throughout Australia. One way to categorize these devices is by sorting them based on whether they are used for surface mining or deep underground mining. Surface mining equipment and technologies are most often used directly to aid in mineral and resource extraction from the earth.

Underground machinery and technologies, on the other hand, are used dozens of meters below the surface and must be built with additional resources and supports since they are significantly more challenging to maintain while underground. Here are some of the most commonly used technologies in modern surface and underground mining.

Surface mining technologies

Haul trucks are among the most eminently recognizable of today’s mining technologies. Colloquially known as dump trucks, these huge vehicles are the largest trucks on the planet. They are specifically used for construction and mining applications that demand structural integrity and the ability to transport massive amounts of debris and resources.

Caterpillar and Komatsu are two prominent manufacturers of haul trucks. These trucks are capable of carrying payloads in excess of 130 tonnes and may have gross operating weights of up to 250,000 kg. The Liebherr T 282 is the single largest diesel-electric truck on the planet, and is capable of carrying up to 326 tonnes in cargo.

Continuous miners are machines with huge rotating steel drums that have rows of tungsten carbide teeth. The teeth revolve rapidly to scrape coal away from the coal seam. These machines work in room and pillar mining systems, and are capable of mining up to 4.5 tonnes of coal every single minute, which exceeds the amount of coal that a miner working in the 1920s could produce after a full day’s work.

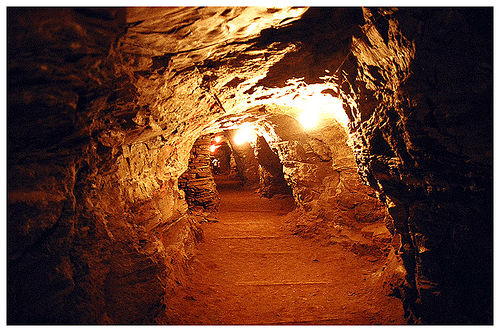

Underground mining technologies

Longwall machines are the most frequently used technologies in modern deep underground mining. They are used in longwall mining, which is a technique for mining coal beneath the surface that is highly effective. Longwall mining machines are essentially sets of coal shearers that are attached to hydraulic ceiling supports that advance through computer control. The process of advancement and shearing is automated and requires very little human intervention.

The machines are more than 200 meters wide and between 1 and 3 meters in height. the mining machines pull out panels of coal; these are rectangular coal blocks that are as wide as the mining machines themselves and up to 3.6 kilometres in length.

The huge shearers rip off coal from underground wall faces and the coal is then transported out of the mine through a network of conveyor belts. The roof supported by the hydraulic panels is allowed to collapse once the longwall mining machine has advanced past a particular section of the panel.

Rock dusters are another crucial technology used in underground mining. They are used in the process of rockdusting, which is when inert rock dust particles are spread and dispersed onto coal dust, which is flammable. Rockdusting is practised to reduce the ability of flames to spread when coal dust is blown away by pressure waves that occur from underground explosions.

Allight mobile lighting towers are available in single or double axle trailers or skid base. They’re all built to withstand harsh climates and terrain challenges.

Comments