Do you remember in Star Trek Voyager when they gave the ship replicators? The premise was that if you are able to break down any element into atoms, then you could rearrange them again to make anything. It was based on their transporter technology, and both technologies are thought to be very close to impossible to create. Without getting into the science of it, it is because isolating and targeting on atom is dangerously beyond our technology. Even today, we need large Hadron Colliders to smash atoms, and even then we are only measuring them, not targeting them.

What do replicators have to do with 3D Printing?

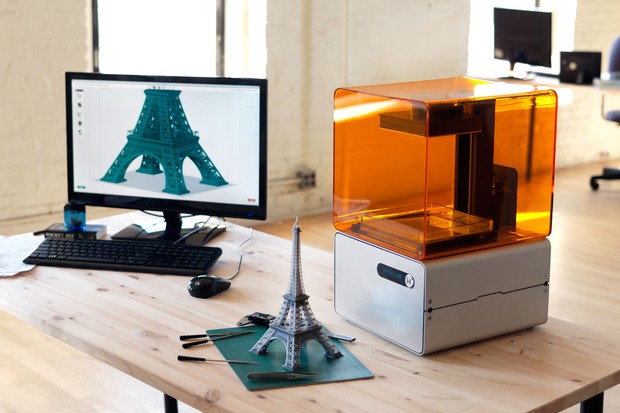

3D printing is the closest thing the human race has ever created that comes close to the replicators on Star Trek Voyager. And even though 3D printing uses a completely different variety of science to Star Trek Replicators, its process and principals are similar. One of the most exciting things is that this is just the start of the technology.

At one point there was a shaky system that connected military computers over great distances. That system evolved into the Internet, the most revolutionary invention that has changed the lives of millions of people in a matter of decades. Once upon a time, movies predicted that phones would not have cords attached to them, and even though the technology started with big brick-like devices that were notoriously unreliable, there are now more mobile phones in America than there are people! One can only imagine what fantastic new technology is going to come of three dimensional printing.

Something just appears from nothing?

This is how the device may appear, but that is like saying that magic is what makes a laser printer print documents. The 3D printer does is add a little layer of plastic every time it runs a cycle. Imagine that you had a piece of paper and you wanted to print the word hello in the middle. Your printer (assuming it is modern) will slightly magnetize the parts of the paper it wants to print the word hello onto. Tiny hard pellet of ink are attracted to the magnetized bit, and are then heated so that they melt and stick. This happens on a tiny scale and creates your printed word.

Now imagine if you did that again with the same piece of paper on the same settings. Each time it was printed, the ink would build up and build up until the words were protruding (embossed) on the paper. This is actually how the 3D printer works. It takes a design from a computer, adds a layer of plastic, then moves up a tiny bit and adds another layer that it melts into the previous layer. Imagine that it is a little like a machine that adds building blocks to walls.

Even though the process is currently reminiscent of the old ribbon printers, there is nothing stopping the design becoming a lot more sophisticated. It is a bit like how there was nothing stopping the old car engines from becoming more sophisticated. All we need is a company to invest a little time and effort into developing the technology a little more. Henry Ford did the same thing with car manufacture and changed the face of the car industry forever. So, one wonders how long it will be before a “Henry Ford” or “Bill Gates” type of person changes the way the 3D printing industry works (it is a very exciting time to be alive).

What is CAD – Computer Aided Design?

We are able to create designs on computers that are three-dimensional models. The measurements we enter can be very specific. We have manufacturing machines that are so precise that they can create very precise objects that are measured very accurately.

The difference that 3D printing is going to make to CAD is the fact that 3D printing works by adding something, whereas most other machine controlled production takes something away. For example, if a machine were creating a rounded rod, then it would polish and strip a bigger piece of metal until it were the correct size and shape. However, 3D printing starts with nothing (almost nothing upon occasion) and then adds bits until it has created its piece. As the technology advances further, it is going to open the door to creating certain articles with an unprecedented precision, and one can only assume that this technique will advance to where metal can be printed.

Why does precision matter?

When machine parts are designed then they need to be as accurate as possible. Later incarnations of 3D printing may help to make some machine parts more precisely measured, but this is important for two very good reasons.

If a working part is off by a fraction of a millimeter then it will not last as long. The machine parts will wear away quickly, and may even break. The more precisely that a piece is measured and created, then the less wear and tear is created. You may not think that that such a small discrepancy would matter, but you have to remember that the part in question may revolve/work 1000 times every day, which means that miniscule imperfections will become problems very quickly.

A machine part that is precisely measured is more efficient. If you have an axel that is very precise, then the surface area of the wear and tear is more evenly spread. This reduces the amount of wear in one specific place, and the smoother resolutions would result in better efficiency. In other words, there would be less energy lost in the process.

John Kravz is a representative of Proessaywriting.com that provides professional help on your writing assignments, like essays, research papers or dissertations.

Comments